SAFETY STOP CONTROL WITH CABLE BREAK DETECTION

The Model RSB is a heavy-duty safety control that provides a positive shut off of dangerous equipment in an emergency. A cable pulled by endangered personnel actuates it. The output contacts of the Model RS can control up to two separate circuits, one for machinery shutdown and one for an alarm The Model RSB has the built-in- advantage of cable break detection.

WHAT IT IS, AND WHAT IT DOES

The Model RSB is designed to act as an emergency stop pull cord control on conveyors and other moving machinery that incorporates built-in broken cable detection. The Model RSB has extension springs, attached to opposite ends of the pull cable, which maintain the cable under constant tension. The RSB is mounted so that it is centered between the end springs. In this way, temperature changes, which cause cable length changes, are canceled out. The operating handle is held in the center vertical position with the internal switch in a normally closed condition. If the cable is pulled or the cable breaks, the handle rotates to release the switch lever. In this way, the alarm signal is generated for either condition. The operating handle must be manually reset back to the center position after the cause has been corrected.

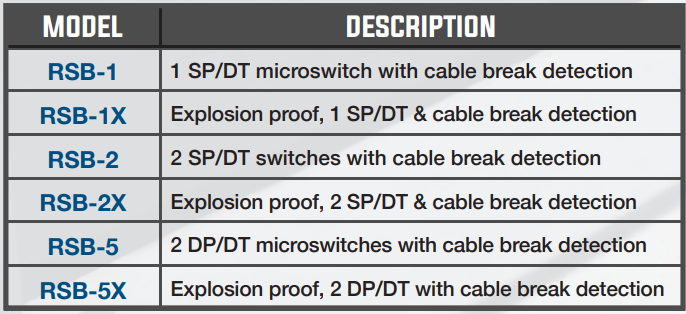

RSB TECHNICAL INFORMATION

Note: Dual-Rated enclosures also available. Contact Sales for details

TECHNICAL SPECIFICATIONS

- The housing is cast aluminum, with optional epoxy or polyester powder coatings available.

- The unit can be actuated via a cable pull from either or both directions on every unit; in other words, the unit is “double ended”. Cable must extend from both sides of the RSB unit.

- The unit is mounted on the conveyor by drilling (3) 13/32” diameter holes. • All units have (3) 3/4” NPT conduit openings.

- The standard units have dry, unpowered SP/DT microswitch(es) rated for 20A @ 120 VAC, 240VAC, and 480 VAC; 1/2 amp at 125 VDC and 1/4 amp at 250 VDC.

- Special spring tensioning kits included with each RSB unit provide stability due to temperature fluctuations, and ease of cable adjustment.

- The functional ambient temperature is -50° to 85° C [-58° to 185° F].

- The general purpose units are rated NEMA type 4/4X weatherproof and corrosion-resistant. Explosion proof units are rated NEMA type 7/9 for dust ignition proof and vapor explosion proof. Specifically, they are listed for Class I, Div. 1, Groups C and D; and Class II, Div. 1, Groups E, F and G. The dual-rated “D” units are rated NEMA type 4X weatherproof and NEMA type 9 dust ignition proof. Specifically, they are listed for Class II, Groups E, F and G.

- The general purpose controls meet or exceed IP65.

- UL listed and CSA listed.